11, Nov 2021

What is screw welding or what is called Stud Welding and the advantages of screw welding

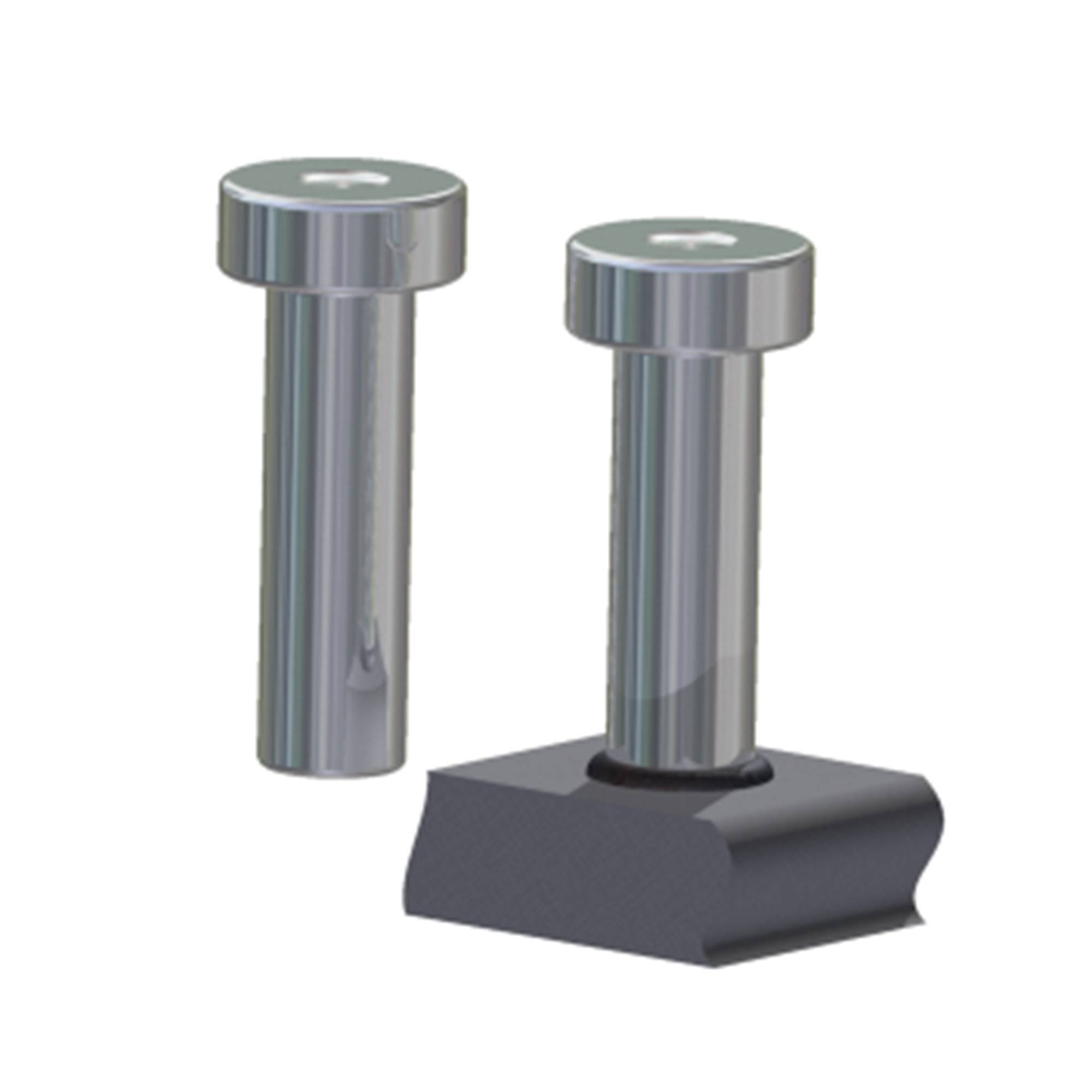

An overview of how to weld a screw

It is the process of fixing nails in metal panels | It is carried out by means of dedicated machines - and the machines consist of a large number

From capacitors to charge a high degree of volts and discharge them all in one moment resulting in the process of fusion of the screw with the metal in contact

And this is one of the ways - we will talk about the types and methods of welding nails

It is characterized by the fact that it is possible to weld nails of different metals to plates composed of different metals as well, and it is not required that the two metals match

Features of Stud Welding

1 - The high speed of fixing the bolts

2 - Fixing nails in metals that are difficult to weld in, or may require hard effort to weld the nail with it

3 - Fastening and quality of nails in thin metals without affecting the metal

4 - lower total cost

5- It only takes a second or two to complete the screw welding process

Types of Stud Welding Machine

1 - Welding by discharging the capacitor, as we mentioned earlier

2 - hollow disc welding

- It is the use of a hollow circular cylinder surrounding the end of the screw - similar to the pottery used in ergo welding

This hollow disk prevents the end of the nail from spreading during its melting, as well as blocking oxygen

This welding is widely used in metals of high thickness